Ultraviolet or “UV” is a type of energy found in the electromagnetic spectrum, lying between x-rays and visible light. Although we cannot see UV light or rays, we are exposed to them every time we step out into the sun. In fact, UV light is responsible for causing sunburns.

UV Water Purification systems use special lamps that emit UV light of a particular wavelength that have the ability, based on their length, to disrupt the DNA of micro-organisms. These UV light waves are also referred to as the Germicidal Spectrum or Frequency. The frequency used in killing micro-organisms is 254 nanometers (nm). As water passes through a UV water treatment system, living organisms in water are exposed to UV light which attacks the genetic code of the microorganism and rearranges the DNA /RNA, eliminating the microorganism’s ability to function and reproduce. If a microorganism can no longer reproduce, it cannot replicate, therefore it cannot infect other organisms with which it has contact. This process of exposing water to UV light is simple but effective, destroying 99.99 percent of harmful microorganisms without adding any chemicals to water.

UV Is Safe

UV disinfection has come a long way since it was first invented. And although UV is a new idea to some, ultraviolet technology has been used for decades by municipal water suppliers and commercial water bottling plants.

While most skin cancers are a result of exposure to UV rays in sunlight, the UV rays in water disinfection UV system do NOT cause cancer. The entire process of exposing water to UV light takes place in an enclosed container posing no risk to family or pets.

UV disinfection is approved by the EPA, and is an environmentally-friendly disinfection method as it is a chemical-free process and creates no byproducts. Because UV is simple, swift and safe, millions of homes and businesses now use ultraviolet technology to disinfect their water.

Chlorine vs UV

There are, of course, different approaches to achieving disinfection. The oldest and most familiar is chlorination or simply adding chlorine (bleach) to your water. This approach has been used by cities and municipalities for years and years. A newer technology that is increasingly being adopted is ultraviolet (UV) disinfection.

Ironically, the science behind UV is just as old as chlorine, but ultraviolet technology has recently come into the mainstream, largely for one reason- adding a chemical to drinking water creates additional problems! The first and perhaps less concerning one has been known all along: your water will taste and smell like chlorine. Secondly, other potentially more harmful chemicals can be produced as a by-product of the disinfection process. Understanding of the detrimental impact of these disinfection by-products continues to grow. UV, on the other hand, is chemical-free and adds no flavor or odor to your water*. Nevertheless, you may be faced with making a choice between these two disinfection techniques. So, how do you decide? Other key considerations will be effectiveness, equipment needs, and maintenance demands.

Effectiveness

Both chlorination and ultraviolet disinfection are effective against harmful bacteria that can be found in well water. However, there are other microbes – not just bacteria – that can find their way into well water and cause very serious illness. You will also want protection from protozoa like Cryptosporidium and Giardia. The latter is especially resistant to chlorine but easily managed with UV. Conversely, some waterborne viruses require higher UV doses to inactivate. In short, you will want protection from as many “bugs” as possible.

Equipment Needs

For disinfection UV, you will be buying a UV water treatment system and likely some form of pre-treatment, which is necessary to ensure optimal functioning of the UV. Pre-treatment can be as simple as including a sediment filter and perhaps a carbon filter, which nowadays often come as one unit. If your water also contains hardness minerals, you will likely also require a water softener. Luckily, there are many additional benefits to softening your water! And for some, there may also be a need to remove iron and manganese. Every circumstance is unique, so you will want to reach out to a water treatment professional to discuss a tailored approach. As a starting point this water treatment selector tool can help you understand your particular needs.

With chlorine disinfection, you will require a chemical feed pump, a solution tank, and a holding tank. The size of these will depend on the size of your home/family and water usage. For optimal performance, you should also add in a static mixer. That’s the chlorination part. Bear in mind that you will still need a water softener for hardness, if that’s an issue in your water. Lastly, you will definitely want to add a carbon filter to avoid tasting the chlorine. By adding more chlorine, this set-up can handle iron-containing waters, but an additional filtration step will be required.

Maintenance

In order to keep any equipment running properly some maintenance will always be required. With a UV system, that can be as minimal as changing the lamp annually and cleaning the quartz sleeve. So how much time is that? Maybe one hour a year. In some cases, it may be necessary to clean the quartz sleeve once every 3-4 months, but that’s only if the water entering the UV system doesn’t fully meet the manufacturer’s specifications.

With a chlorinator, besides the time spent regularly refreshing and monitoring the chemical supply, you should thoroughly clean the system twice a year and give it a complete inspection for any signs of corrosion. Just like chlorine is hard on the “bugs”, it can be hard on your pump and other metals too.

Comparison Chart

The following chart compares these two commonly used approaches – UV and constant chlorination. For many, getting effective disinfection without the use of chemicals is enough to sway their decision. But it is easy to see how the low maintenance requirements of a UV system would totally tip the scales.

| Key Considerations | Chlorine | UV Disinfection |

| No Chemicals | NO | YES |

| Effectiveness

vs Bacteria vs Protozoa vs Viruses |

YES Cryptosporidium highly resistant YES |

YES YES Some viruses require higher UV doses |

| Equipment Needs | Chemical feed pump

Solution tank Holding Tank w/ static mixer Carbon filter |

Pre-treatment must include sediment and carbon filter and may include water softener and iron removal. |

| Maintenance | Regular chemical handling

Thorough cleaning twice/year Cleaning all surfaces showing corrosion Cleaning any clogged injection points |

Yearly lamp replacements

Occasional quartz sleeve cleaning or replacement |

*In rare circumstances, low levels of sulphur in source water may become detectable due to the UV system.

What are the parts of UV System?

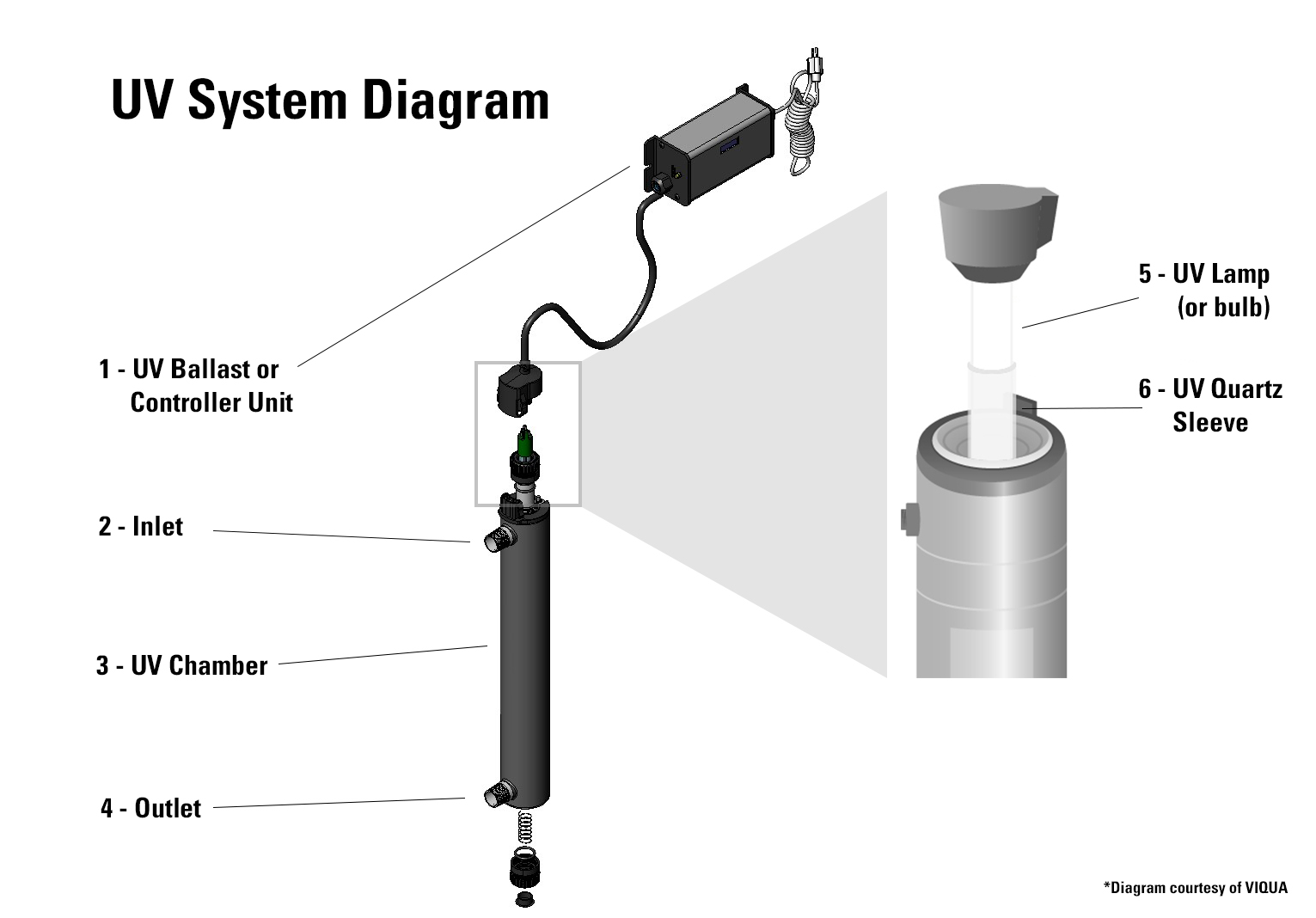

There are a variety of ultraviolet water purification system makes and models, but most of them have the same basic components. Here is a list of the nine most common components on UV disinfection systems:

- UV Ballast or Controller Unit – This is the “brains” of the UV system. Some systems have a very simple controller, and others have a more complicated system that includes alarms, lamp change timers, trouble indicator lights, and more. Although UV units vary in complexity and size, all controllers do basically the same thing of controlling the electrical output of the lamp and powers the UV-C light needed for water purification.

- Inlet for untreated water.

- UV Chamber – This part of the system houses the UV sleeve and lamp, and also controls the flow of water through the system.

- Outlet for treated (clean) water.

- UV Lamp (or bulb) – The lamp of a UV system produces UV-C, which is UV light considered to be germicidal. However, different lamps perform different functions, so they type of lamp used will be contingent on the application and disinfection requirements

- UV Quartz Sleeve – The quartz sleeve of a UV system is the long, cylinder-shaped tube. The tube is made of quartz glass and is there to protect the UV lamp which is powered by electricity from the flow of water. The UV lamp transmits light through the tube into the water. It is important to clean the sleeve (generally when the lamp is changed) as minerals and contaminants in the water can cloud the glass tube.

- UV Sensor – Available option on most UV systems, the UV sensor monitors and indicates the intensity of the UV light. If the intensity becomes too low, even though the lamp is on, an alarm is triggered.

- Solenoid Valve – Available option on most UV systems, the solenoid valve automatically shuts the water off if the system is not functioning properly, preventing the possibility of contaminated water flowing through the system that is not treated properly.

- Flow Meter – Standard on some UV systems, the flow meter calculates the actual real-time UV dose delivered for a particular flow rate, ensuring water is treated properly.

Do you want to choose your UV System ?

You should choose Aquafine for industrial applications, and Viqua for residential applications from IWTE.

WHY?!

- High-quality products which meet international standards.

- Availability of spare parts.

- Maintenance services.

- Customization options.

- Variety of products, features, and prices.

- Arabic Manuals for Aquafine Products.

Download the latest success Aquafine UV cases in Egypt.

For more information, contact us at [email protected]